Time is often critical – and this is exactly where we excel. With an exceptionally large, well-stocked inventory of metals, alloys, plastics, composites, stone and ceramics, we are ready to start immediately. This enables us to complete express orders within a very short time – if required, within 24 hours.

Our machine fleet of around 50 state-of-the-art systems is deliberately designed with overcapacity. For you, this means maximum flexibility, short reaction times and the assurance that your deadlines will be met reliably – even when time is extremely tight.

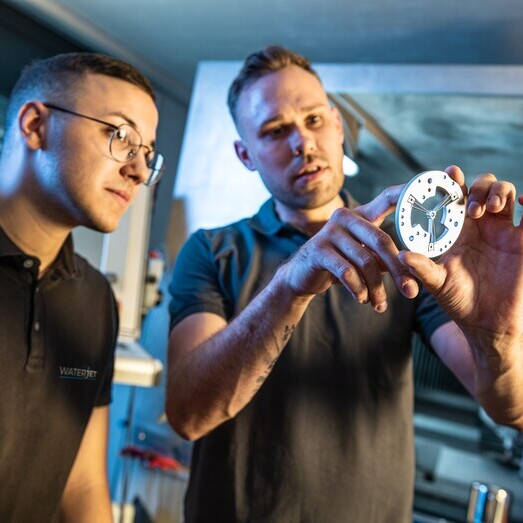

Thanks to this combination of inventory, technology and organization, we deliver not only quickly but also consistently in the highest quality. Your requirements are always at the centre – whether a short-notice prototype, an urgent small series or a complex project. We ensure your ideas take shape without delay.