We use cookies to make our website user-friendly, to continuously improve it, and to analyze visits to our website. By using our services, you agree to this.

-

Materials

-

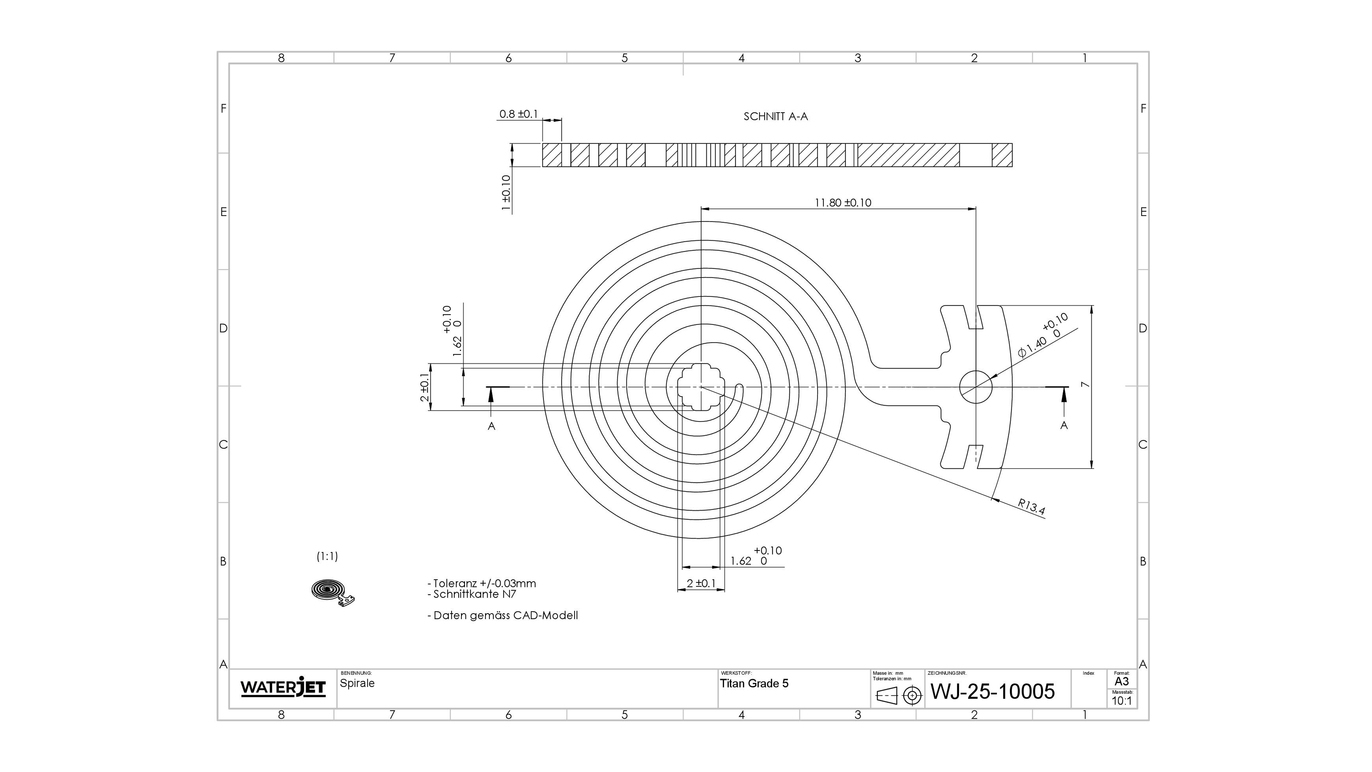

Capabilities

- Industries

- Inspiration

-

Company