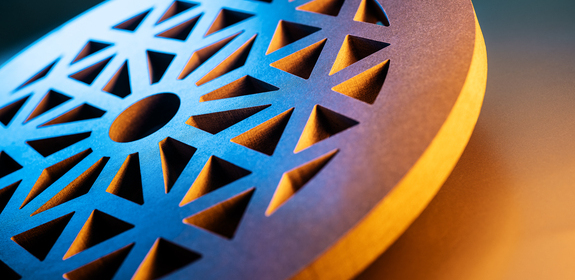

Our strength begins with the material itself. With one of the largest and most varied material inventories in the industry, we are ready to deliver immediately – without waiting times or detours.

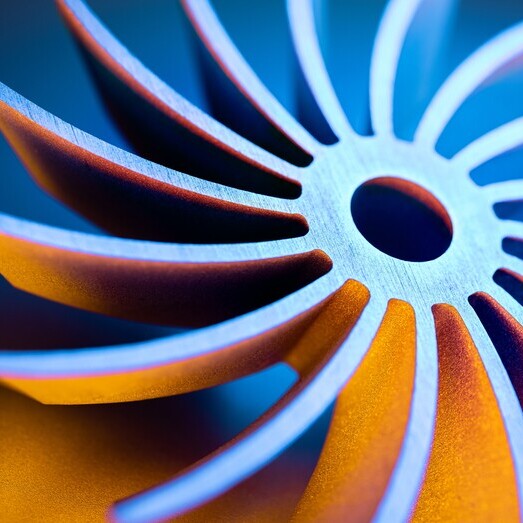

Whether metals and alloys, plastics, composite materials or stone and ceramics – we maintain a wide range of materials in various thicknesses and formats.

This variety makes us highly flexible and gives you the certainty that even short-notice projects can be realized. For express orders in particular, this enables fast turnaround times. You also benefit from our extensive knowledge of different material properties – we advise you on the most suitable material for your application.

With our material availability, we ensure that your ideas do not fail due to long supply chains but can be implemented quickly and directly.