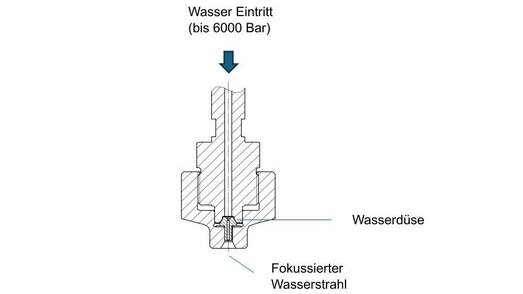

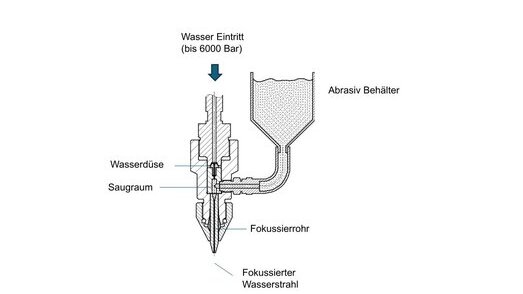

Pure waterjet cutting is the original form of waterjet technology and is defined by its purity. Using a fine jet with pressures of up to 6,000 bar, materials are cut without heat, discoloration or mechanical stress. The material structure remains unchanged – a key advantage over thermal processes such as laser cutting.

This method is ideal for soft and sensitive materials such as plastics, rubber, foams, textiles, leather or paper. It is also widely used in the food industry – for example in the precise cutting of baked goods, pastries or frozen products, where hygiene and product integrity are critical.

Its advantages include high cutting precision, clean edge quality, minimal kerf width, no thermal distortion and maximum material protection. Pure waterjet cutting also offers economic benefits by reducing scrap and minimizing rework.

Whether in industrial applications or food processing, pure waterjet cutting is the ideal solution wherever precision and material integrity are essential.